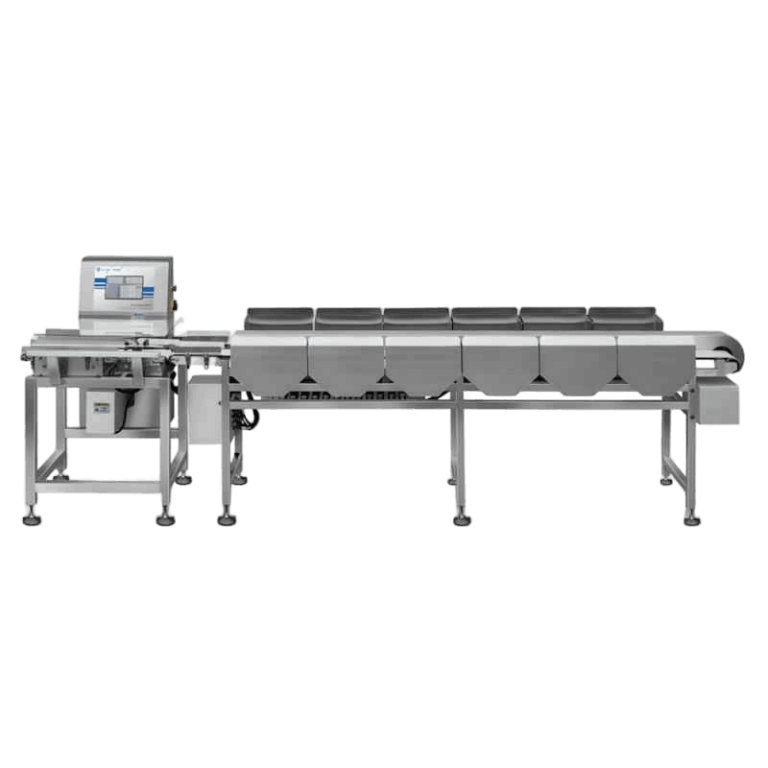

Fundamentally, a sorter machine automates the separation of products based on specific criteria such as weight, size, or shape. For operations relying on WEIGHT SORTING, understanding the internal architecture of this equipment provides insight into its reliability and application potential. This breakdown examines the primary subsystems that constitute a standard weight-based sorter machine.

The Infeed and Product Handling System

The process begins at the infeed system, which controls the presentation of items onto the sorter. This component ensures products are singularized and spaced correctly before they enter the weighing zone. A consistent and stable infeed is critical; without it, the accuracy of the entire WEIGHT SORTING operation can be compromised. This section often includes vibratory feeders, conveyor belts, or staging lanes designed to handle the specific product type.

The Integral Weighing Mechanism

At the heart of the apparatus lies the weighing mechanism itself. This typically consists of a high-precision load cell connected to a weighing platform or conveyor segment. As an item passes over this platform, the load cell measures its force, converting it into an electrical signal. The system’s software then interprets this signal to determine the product’s mass. The sensitivity and calibration of this mechanism directly dictate the sorting accuracy for a given sorter machine.

The Diversion and Outfeed System

Once a weight value is registered, the diversion system activates. This component is responsible for physically moving the product into its designated category. Common methods include air jets, push arms, pivoting flaps, or diverter arms. The choice of technology depends on factors like product fragility, required speed, and the number of sortation bins. This stage executes the final decision, completing the automated WEIGHT SORTING process.

Grasping the function of these core components—infeed, weighing, and diversion—allows businesses to better assess their automation needs. This knowledge supports more informed conversations with equipment providers regarding the capabilities of a sorter machine suitable for their specific production line.