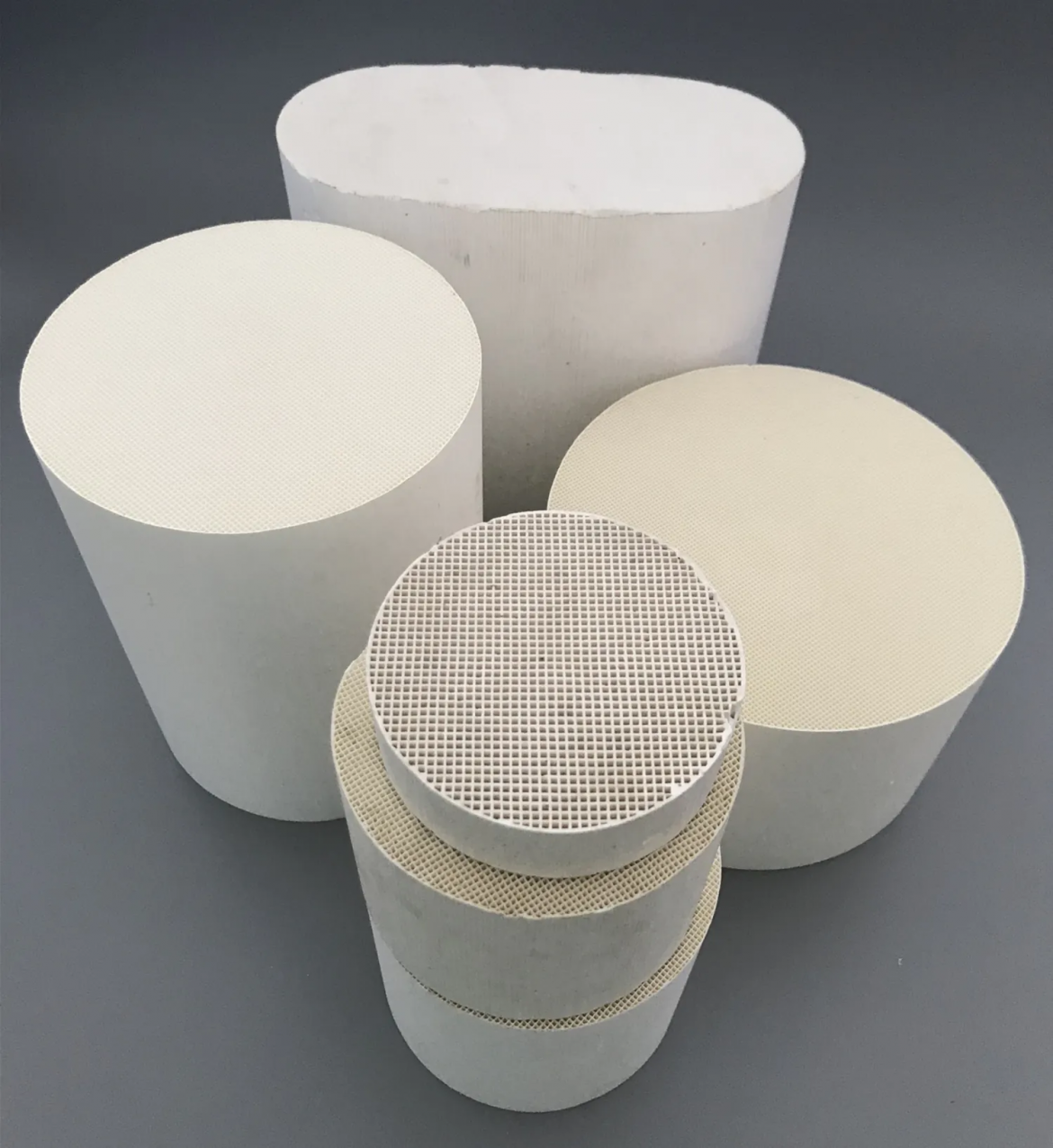

Manufacturing catalytic converters involves several stages that ensure efficient emission control while meeting strict environmental standards. As a catalytic converter company, they focus on preparing a durable metal or ceramic substrate, which is then shaped into a honeycomb structure to maximize surface area. This structure is coated with a washcoat that improves the adherence of active catalytic materials. When discussing established catalyst manufacturing companies, the process often includes precision slurry preparation and controlled high-temperature treatments to ensure stability. These steps form the foundation of a converter capable of supporting modern engine performance and long-term reliability.

Coating and Activation of Catalyst Materials

After forming the substrate, the next stage involves applying a carefully engineered coating that holds precious metal catalysts. They ensure the mixture is evenly distributed so exhaust gases can interact efficiently with the active layer. A catalytic converter company typically uses dedicated drying and calcination procedures to stabilize the coating and improve bonding strength. Among experienced catalyst manufacturing companies, this stage is essential for maintaining consistent conversion efficiency. At this point, different filter modules may be integrated depending on the application, such as the SiC/Cordierite DPF (diesel particles filter) designed to capture soot and fine particles. This filter, using a wall-flow honeycomb structure, supports Euro IV–VI compliance by trapping more than 95% of particulates while preserving engine performance.

Material Options for DPF Integration

When converters are used with diesel engines, they often incorporate particulate filters that match the vehicle’s operating conditions. They provide Cordierite DPF units known for lightweight construction, thermal-shock resistance, and suitability for urban driving. Silicon Carbide options offer higher mechanical strength and better thermal conductivity, aligning with the needs of heavy-duty engines. Both designs are compatible with the manufacturing workflow followed by reputable catalyst manufacturing companies, ensuring reliable emission reduction.

ConclusionIn summary, catalytic converters are manufactured through substrate preparation, catalyst coating, and thermal activation, with each step supporting stable emissions control. Experienced producers like Hualian Catalyst align every procedure with engineering and regulatory needs. Whether using SiC or Cordierite filters, a trusted catalytic converter company ensures the final system performs efficiently. This reflects how modern catalyst manufacturing companies integrate material science and practical design to deliver dependable converter solutions.