Replacing heavy steel and aluminum chassis components with high-performance thermoplastics allows manufacturers to reduce vehicle weight by 30% to 50%, directly translating to a significant increase in Electric Vehicle (EV) battery range. By utilizing advanced automotive injection molding processes early in the design phase, engineers can leverage high-strength engineering resins to achieve superior strength-to-weight ratios. This strategic shift optimizes energy efficiency while enabling part consolidation and complex geometry integration that traditional metal machining simply cannot achieve.

Optimizing EV Range Through Strategic Metal Substitution

Reducing curb weight is the most effective method to offset the heavy mass of lithium-ion battery packs. Manufacturers leverage advanced polymers to replace non-critical metal structures, directly improving energy consumption per mile without sacrificing safety or durability.

Lowering Curb Weight with Fiber-Reinforced Polymers

Replacing stamped metal brackets and housings with long-fiber reinforced thermoplastics (LFRT) offers immediate mass reduction. Engineering data indicates that converting a steel control arm to a carbon-fiber-reinforced polymer composite can yield weight savings of over 40% while maintaining equivalent tensile strength. This reduction is critical; industry studies suggest that a 10% reduction in overall vehicle weight can improve EV range by approximately 6% to 8%.

| Component Type | Material Replacement | Est. Weight Saving |

| Mounting Brackets | Steel to PA66-GF30 | 45% |

| Sensor Housings | Aluminum to PBT | 35% |

| Battery Trays | Steel to PP-LGF | 50% |

Enhancing Suspension Efficiency via Unsprung Mass Reduction

Targeting unsprung mass—components not supported by the suspension, such as wheels and brake cooling ducts—maximizes efficiency. Plastic injection molding for automotive suspension parts, like stabilizer links, reduces inertia. Lower unsprung mass allows the suspension to react faster to road irregularities, improving both ride quality and the vehicle’s energy management profile.

Engineering Resins for High-Voltage Structural Applications

As EV powertrains operate at increasingly higher voltages (800V+), materials must possess exceptional dielectric strength and thermal stability. Plastic injection molding automotive industry standards now demand resins that survive extreme environments while preventing electrical arcing.

Dielectric Strength and Thermal Stability in Powertrain Connectors

High-performance thermoplastics like PEEK (Polyether Ether Ketone) and PPS (Polyphenylene Sulfide) are essential for high-voltage connectors and busbar insulation. PEEK maintains mechanical properties at continuous service temperatures up to 260°C, far exceeding standard nylons. Its superior dielectric strength prevents breakdown under high voltage loads, a critical factor for preventing short circuits in compact motor inverters.

Flammability Standards for Battery Module Carriers

Battery components must adhere to rigorous safety standards, specifically the UL 94 V-0 flammability rating, which ensures self-extinguishing properties within 10 seconds. PPS is widely favored here because it achieves V-0 ratings inherently without the need for halogenated additives that can degrade mechanical ductility. This makes it ideal for injection molding automotive parts like module carriers that require both structural rigidity and fire resistance.

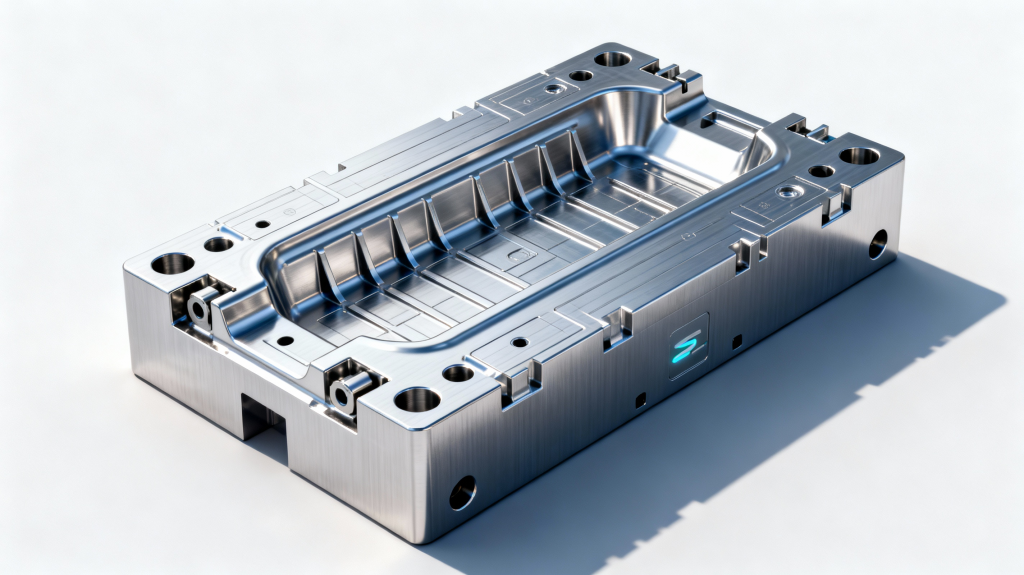

Precision Manufacturing Excellence at Livepoint Tooling

Livepoint Tooling stands as a premier partner for global automotive OEMs, delivering integrated manufacturing solutions from concept to mass production. With over 23 years of expertise and IATF 16949 certification, the company specializes in high-precision automotive injection mold fabrication and thermoplastic processing.

Core Capabilities and Highlights:

End-to-End Solutions: From rapid prototyping and DFM analysis to high-volume manufacturing, ensuring seamless scalability.

Advanced Technologies: Expertise in multi-cavity molds, insert molding, and overmolding for complex assembly consolidation.

Global Standards: Proven track record supplying Tier 1 suppliers and luxury automotive brands, guaranteeing strict adherence to tolerance and surface finish requirements.

Material Mastery: Extensive experience processing high-performance engineering resins (PEEK, PPS, PEI) for critical electrical and structural applications.

By combining robust quality assurance with rapid tooling capabilities, Livepoint Tooling helps engineers accelerate development cycles and achieve aggressive weight-reduction targets.

Conclusion

To fully realize the range-extending benefits of metal-to-plastic conversion, partner with a manufacturer that combines material expertise with precision tooling capabilities. Selecting the right automotive injection molding suppliers ensures that components not only meet weight targets but also deliver the structural reliability required for next-generation electric vehicles.