Valve selection often involves understanding the core mechanisms that define performance. For those considering a ball valve floating ball design, knowing how it contrasts with the trunnion-mounted alternative is a fundamental step. This analysis outlines the primary mechanical differences between trunnion and floating ball valve types, providing clarity for specification needs.

The Fundamental Mechanical Principle

The key distinction lies in how the ball is supported within the valve body. In a floating ball valve, the ball is not fixed to the stem at its base. It is free to move or “float” slightly along the shaft axis. When the valve is closed, upstream pressure pushes the ball against the downstream seat, creating a tight seal through this mechanical displacement. This simple and effective design is a hallmark of many standard ball valve floating ball applications.

Handling Different Pressure Ranges

This mechanical difference directly influences pressure capacity. The floating ball valve design relies on seat deformation for sealing, which makes it well-suited for low to medium-pressure services. In contrast, a trunnion-mounted ball valve features a ball that is fixed on a supported shaft (the trunnion). This anchored design prevents the ball from shifting under high pressure, transferring force to the trunnion and bearings, which allows it to manage much higher pressure classes effectively.

Typical Applications and Use Cases

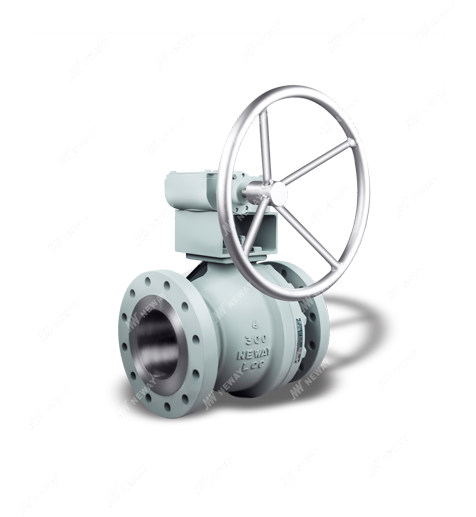

Consequently, the application scope for each valve type diverges. The simplicity of the floating ball valve makes it a cost-efficient and reliable solution for many standard industrial pipelines, water systems, and lower-pressure process flows. Trunnion-mounted valves are typically specified for critical, high-pressure environments such as mainline oil and gas transmission, large-diameter pipelines, and systems where operational safety under extreme pressure is the primary concern.

Grasping the operational principles between floating and trunnion-mounted ball valves provides a solid foundation for equipment selection. Neway Valve manufactures both valve types, ensuring a robust solution for a wide spectrum of industrial requirements and pressure demands.