Companies often require energy sources that match their unique applications. Gushine specializes in this area, creating tailored power for a wide array of sectors. With a history of over 3,500 successful deliveries across fourteen years, their approach to custom battery solutions is both structured and collaborative. This process ensures that each power pack meets precise specifications for devices in fields like medical equipment, industrial terminals, and consumer electronics.

Initial Needs Analysis and Quotation

The first phase involves a detailed discussion of requirements. Clients provide their specific needs regarding voltage, capacity, dimensions, and application context. Gushine engineers analyze this information to formulate a detailed proposal. This initial step is fundamental to defining the project’s scope and providing a clear quote for the custom lithium battery solutions. The focus remains on the product’s intended use to ensure the design is fit for purpose.

Collaborative Sample Development

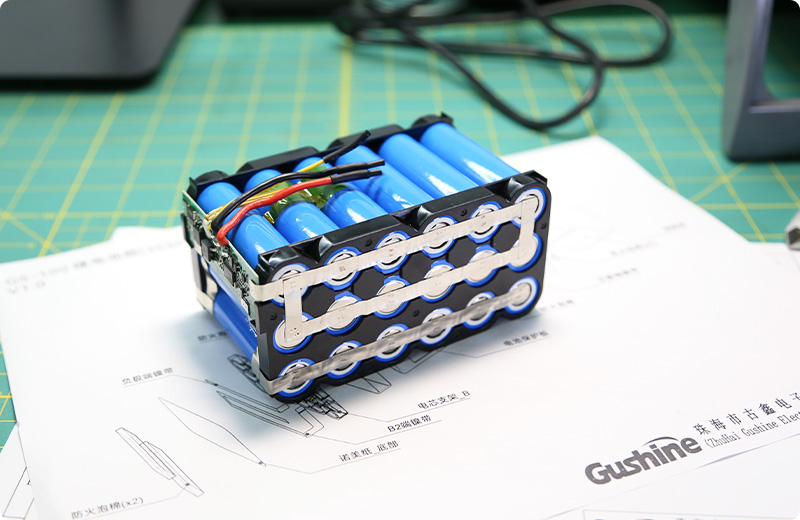

After the plan is approved, the sample production stage begins. Gushine believes in a transparent and cooperative development process. Clients work directly with professional engineers to monitor progress and understand every detail. The company then produces functional samples for rigorous client-side testing. This hands-on phase allows for practical validation and any necessary refinements before moving forward.

Successful sample testing leads to trial production. Here, the agreed-upon custom lithium battery solutions are built in a small batch to confirm consistency and quality. Gushine also manages the required certification procedures during this stage. Once the trial units receive final confirmation, the order progresses to mass production. Gushine‘s flexible production lines capably handle both large and small volume orders, concluding with secure and timely shipment after payment.